3D Printer with Multi-Paste Extruder

I believe that it is imperative for artists and designers to understand the language, protocols, and methods of production currently used by architects, engineers, and computer scientists. One approach is to teach artists to build machines that show how traditional methods – eg. contemporary craft – can be fused with emerging technologies to create new approaches and hybrid works. This approach also opens up a productive dialogue between artists, engineers, and scientists to investigate methods of collaboration between disciplines.

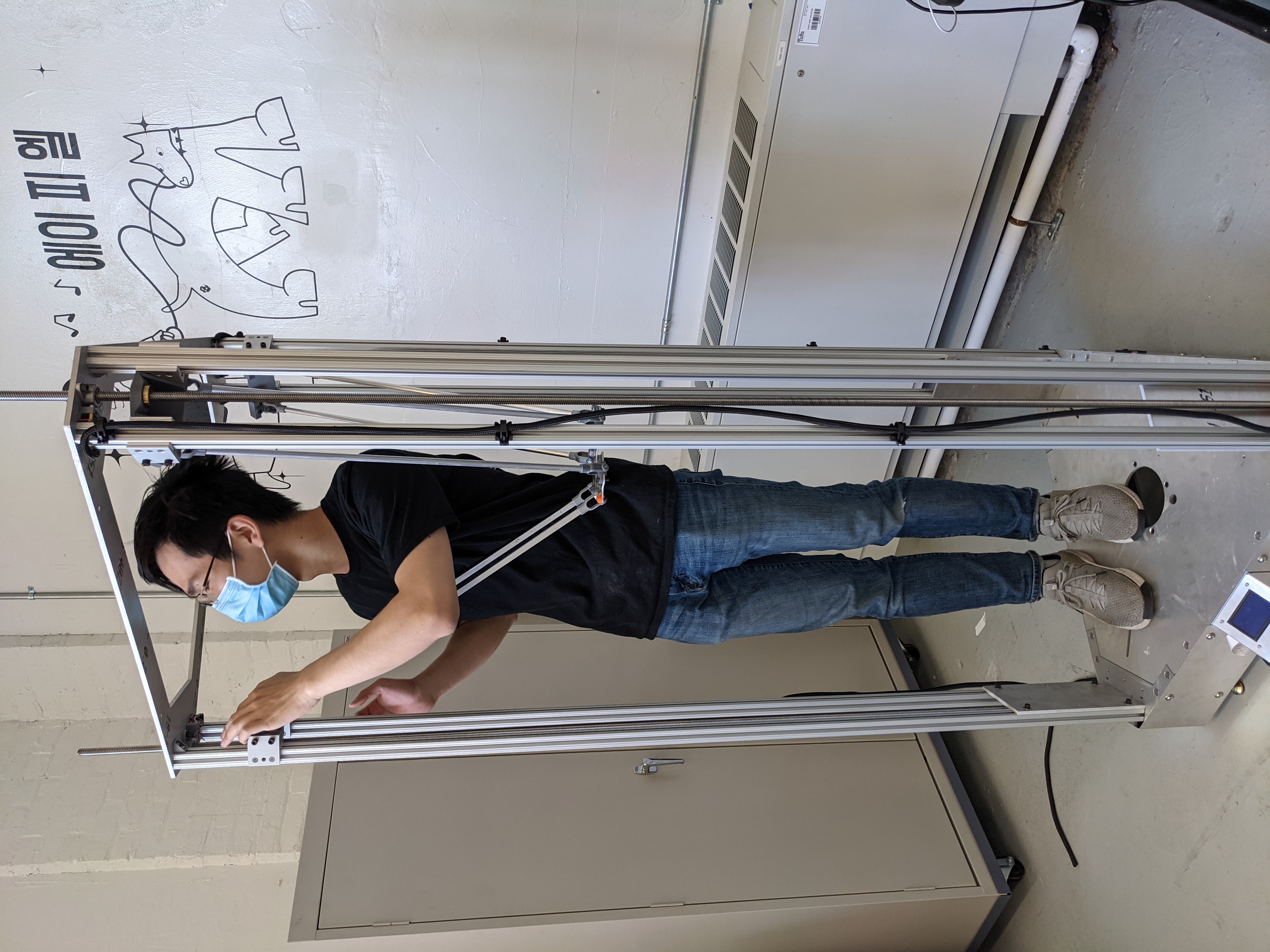

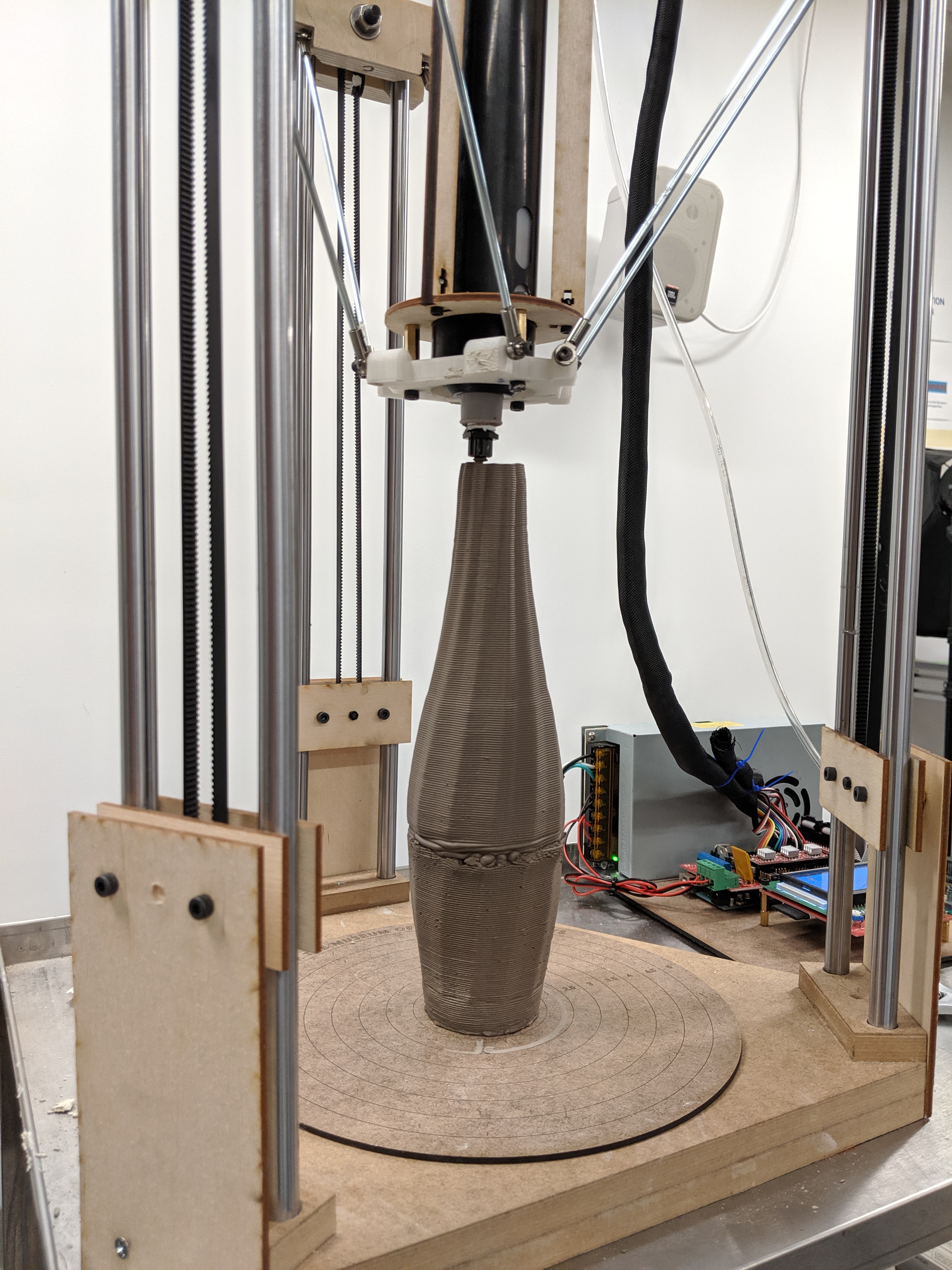

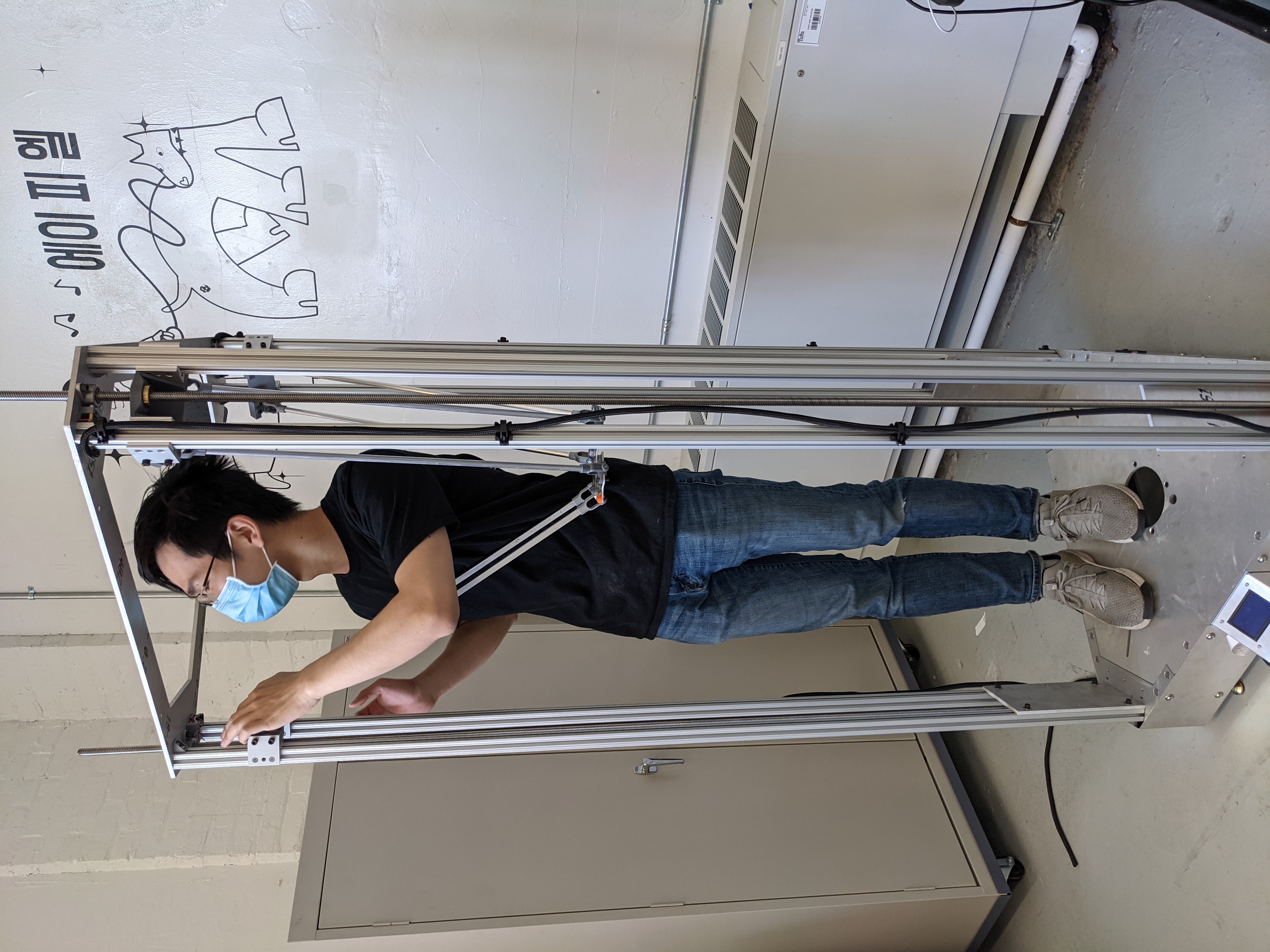

In collaboration with students at the Tufts School of Engineering. Prototyping and building of a small-scale 3D cermics printer, and a large-scale multi-paste extruder. The small Delta 3D Ceramics Printer lasted about 2 months from initial build to actual printing. We were able to print several small ceramic pieces that can now be treated like any other traditional ceramic work (glazing, firing, etc.)

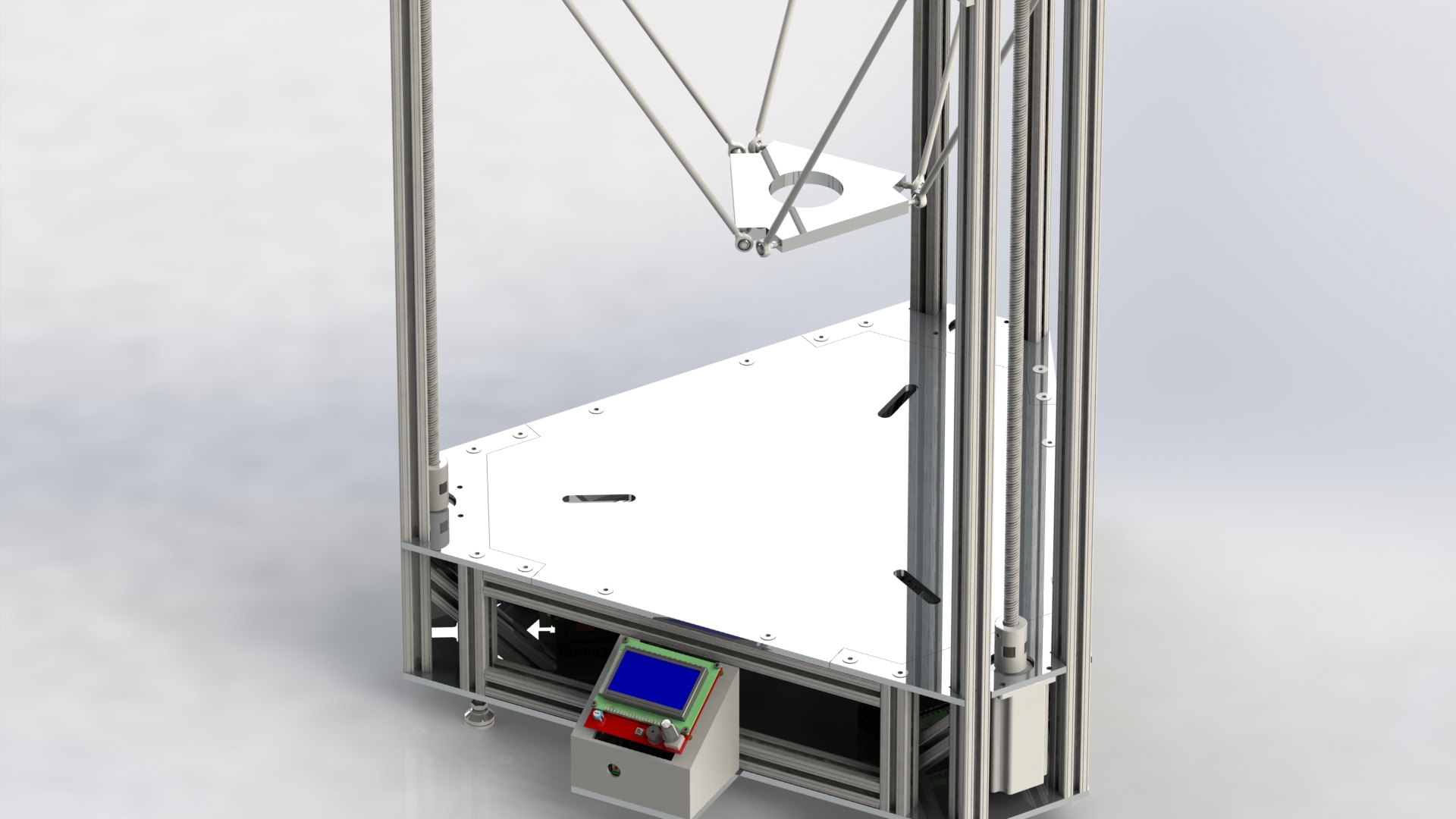

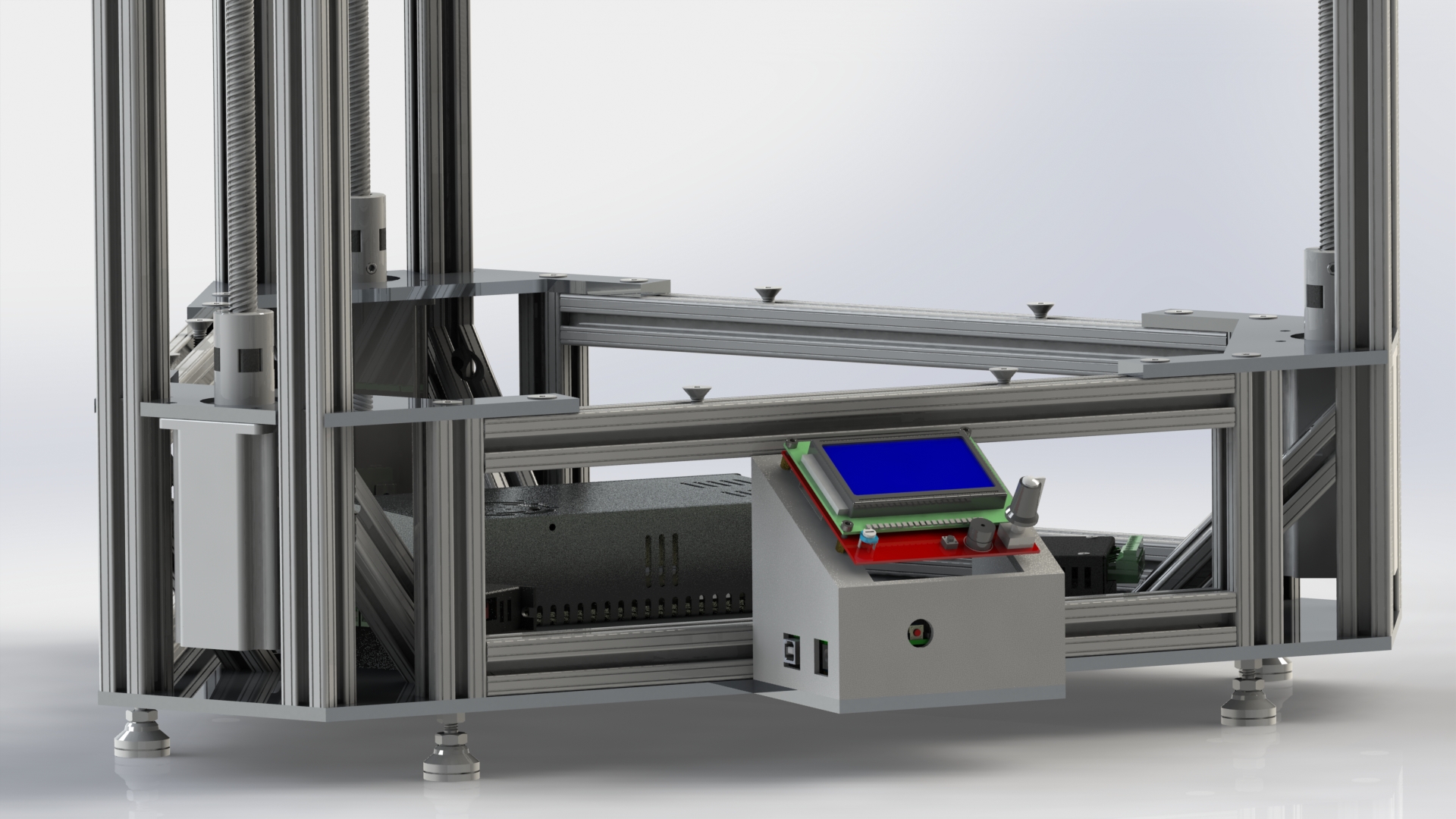

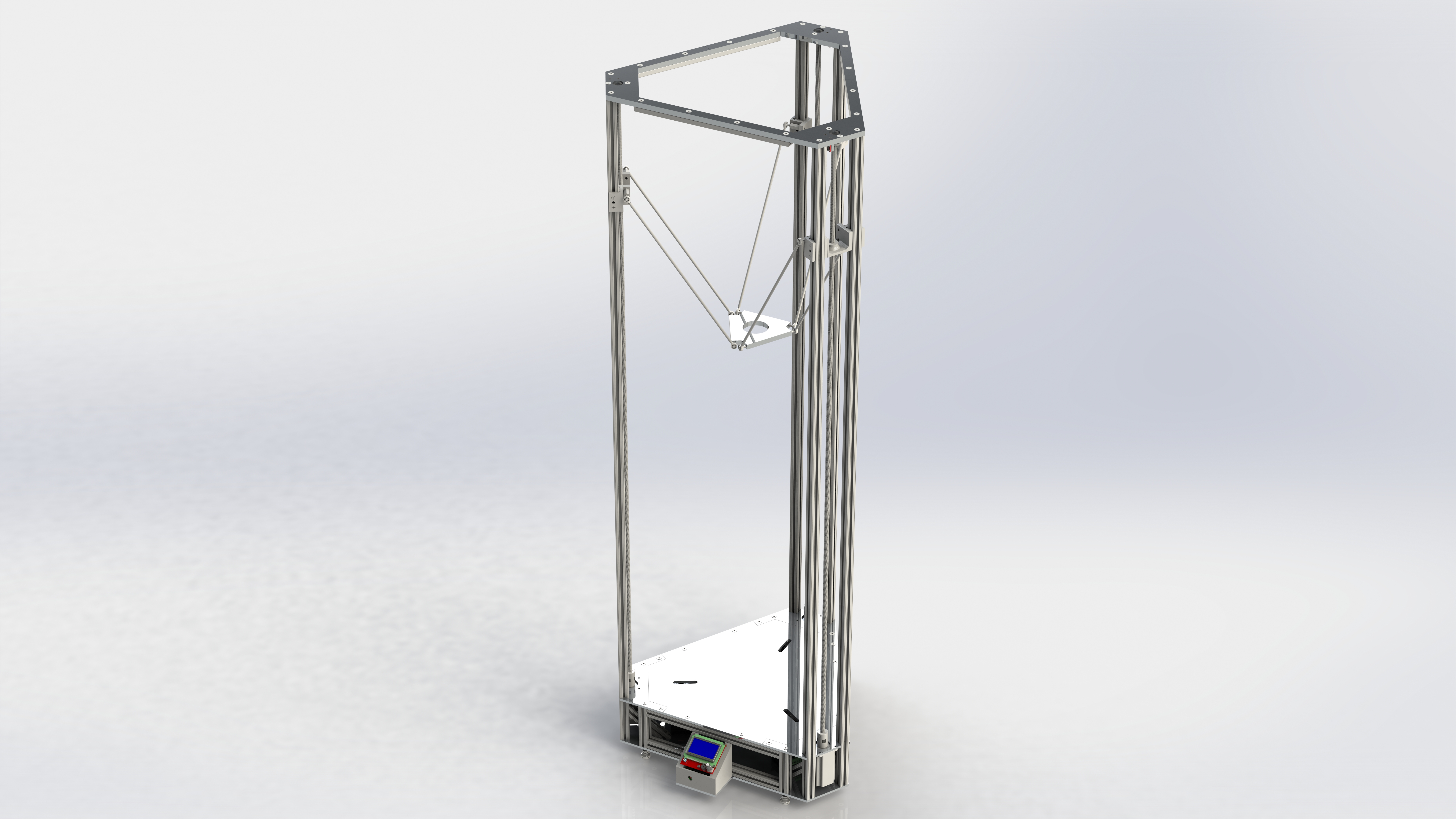

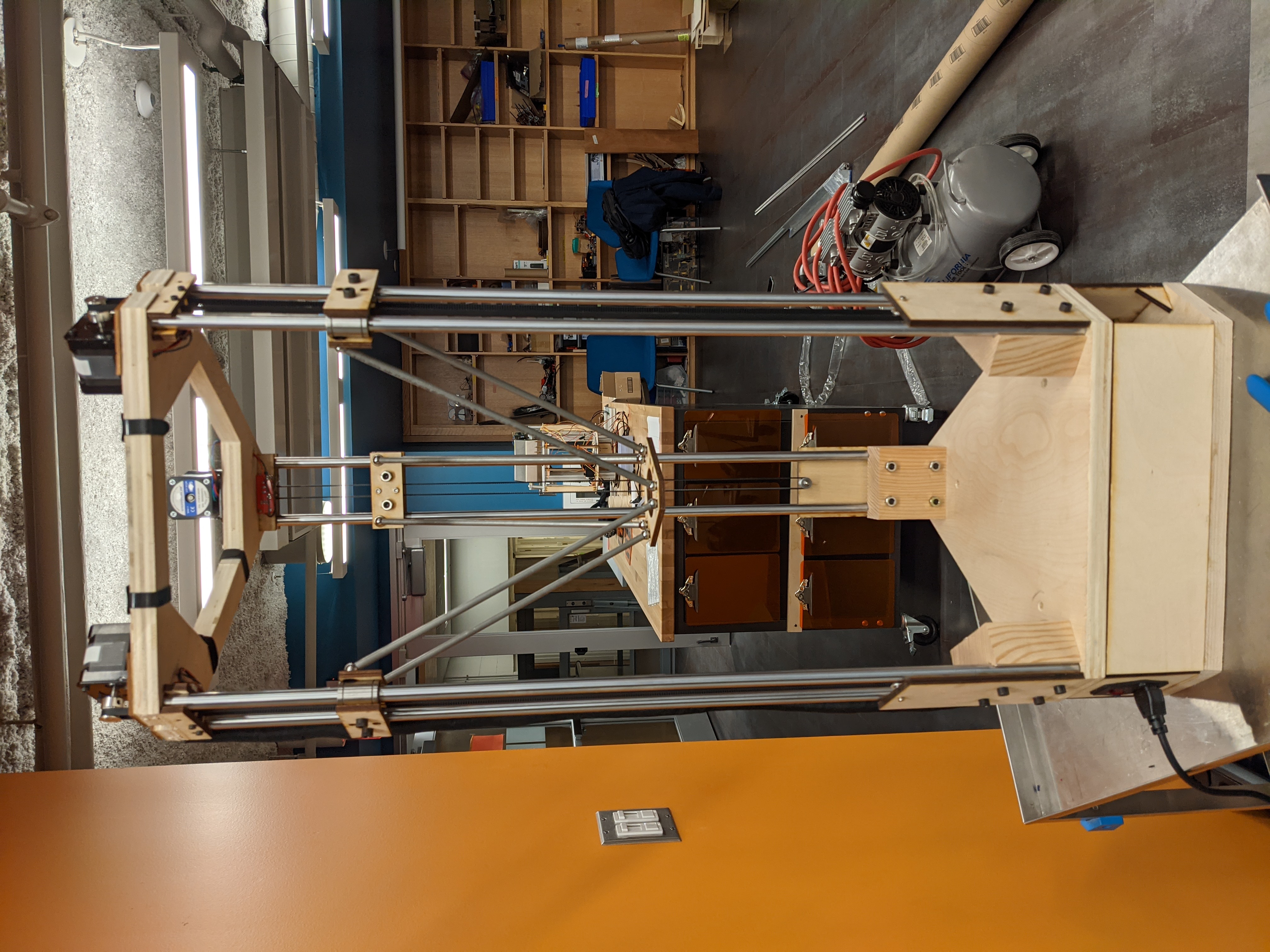

We then prototyped and built a large-scale version of the Delta ceramics 3D printer. The finished machine will be housed within the digital fabrication lab at the School of the Museum of Fine Arts where students and other faculty can start to experiment and engage with digital fabrication using sustainable materials. The printer is capable of printing objects up to 4’ high and 3’ wide.